Introduction

Engineering changes are inevitable. Customer requirements evolve, materials change, and designs improve. The challenge is not managing change—it is managing change well. Many engineering teams experience delays, confusion, and errors because change processes are informal or inconsistent.

The Problem With Informal Change Processes

Common practices include verbal instructions, emails without traceability, or manual approval checklists. Over time, these approaches break down, especially when multiple stakeholders are involved.

Consequences of Poor Change Control

Without a structured process:

- Teams lose visibility over what has changed

- Manufacturing may work on outdated information

- Accountability becomes unclear

- Audit trails are incomplete or non-existent

These risks grow significantly in regulated or complex manufacturing environments.

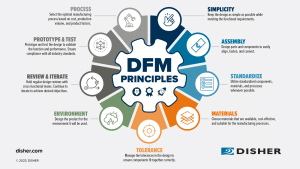

What an Effective Change Process Includes

A practical engineering change process provides:

- Clear request and approval workflows

- Impact assessment before implementation

- Traceability between changes and affected files

- Visibility across departments

Importantly, the process must support engineering—not hinder it.

Technology as an Enabler, Not the Goal

Digital workflows integrated with design data ensure that approved changes are reflected immediately in drawings and models. This reduces manual intervention and improves confidence across teams.

Cultural Alignment Matters

Even the best systems fail if teams are not aligned. Clear communication, role definition, and training are essential to ensure change management becomes a habit, not a burden.

Closing Thought

Change management is not about bureaucracy—it is about reducing uncertainty and protecting business outcomes.

A review of your current engineering change process can reveal improvement opportunities that deliver immediate value.