Introduction

Engineering and manufacturing often share the same goal—delivering quality products on time—yet misalignment between these teams remains common. Bridging this gap is one of the most impactful improvements a manufacturing organisation can make.

Where Misalignment Begins

Problems often start with unclear design intent, late design changes, or incomplete documentation. Manufacturing teams may receive drawings without context, leading to interpretation errors.

The Cost of Poor Collaboration

When engineering and manufacturing are disconnected:

- Production delays increase

- Rework becomes common

- Quality issues go unnoticed until late

- Trust between teams erodes

These issues affect morale as much as performance.

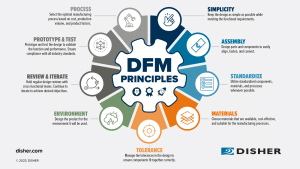

Creating a Shared Engineering Language

Effective collaboration starts with shared expectations. Design standards, clear documentation, and structured approvals ensure manufacturing receives accurate, approved information every time.

Digital Systems as Collaboration Bridges

Integrated design and data platforms allow manufacturing teams visibility into design changes. Collaboration is no longer dependent on emails or manual updates.

Cultural Alignment Is Equally Important

Technology alone is not enough. Regular cross-functional reviews, shared objectives, and early involvement foster stronger working relationships.

Closing Thought

Engineering excellence is only fully realised when it translates seamlessly into manufacturing success.

Improving collaboration often begins with reviewing how design information is handed over today.