Introduction

In manufacturing organisations, the difference between an average engineering team and a high-performing one is rarely about individual talent alone. More often, it comes down to clarity, consistency, and the systems that support how work gets done.

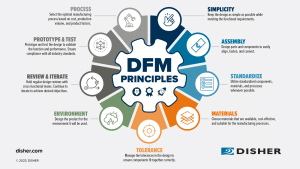

Clear Standards, Not Individual Workarounds

High-performing teams do not rely on personal file naming habits or undocumented processes. They operate with shared design standards, common templates, and agreed workflows. This ensures work remains consistent regardless of who is assigned to a project.

Strong Ownership of Engineering Data

Responsibility for files, revisions, and approvals is clearly defined. Designers know what they can edit, what must be reviewed, and when a design is formally released. This reduces uncertainty and prevents accidental mistakes.

Collaboration Beyond Engineering

Engineering does not operate in isolation. High-performing teams actively collaborate with manufacturing, purchasing, and quality. Design intent is communicated early, reducing downstream surprises.

The Role of Digital Tools

Tools such as SOLIDWORKS support design efficiency, but productivity improves significantly when paired with structured data management and collaboration workflows. Integrated platforms reduce manual handovers and eliminate ambiguity.

Continuous Skills Development

These teams invest in ongoing training—not just for software usage, but for best practices. This ensures skills remain relevant as tools and requirements evolve.

Closing Thought

High-performing engineering teams are built through discipline, alignment, and the right systems—not overtime and heroics.

Evaluating how your engineering team currently works is often the most effective starting point for long-term improvement.