Introduction

Many manufacturing organisations in Malaysia still rely heavily on 2D drafting. While 2D tools remain relevant, increasing product complexity and collaboration needs are driving teams to rethink how design information is created, shared, and reused.

The Strengths—and Limits—of 2D Drafting

2D drafting excels in:

- Layout-driven designs

- Legacy documentation

- Fast conceptual work

However, limitations emerge when designs require frequent updates, cross-department collaboration, or downstream reuse.

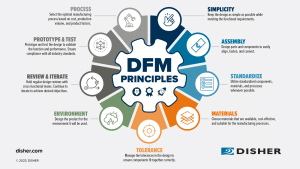

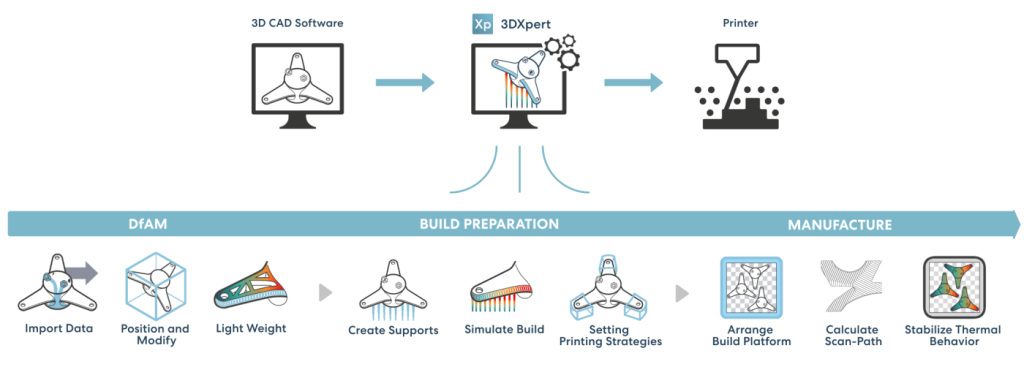

Why Integration Matters

Modern design workflows connect 2D and 3D data within a broader engineering context. Changes made in one area propagate consistently, reducing errors and duplication.

Supporting Mixed Design Environments

Transitioning does not mean abandoning 2D. Many successful teams use tools like DraftSight alongside 3D CAD systems, allowing flexibility while maintaining consistency.

Business Benefits of Integrated Workflows

- Faster design iterations

- Improved communication with manufacturing

- Better reuse of engineering knowledge

- Reduced dependency on individual expertise

A Realistic Transition Path

Effective evolution begins by identifying workflows that benefit most from integration. Training, process alignment, and tool selection should support gradual adoption—not disruption.

Closing Thought

The goal is not to replace tools, but to build workflows that support how engineering teams actually work.

If your organisation is considering how to better connect 2D and 3D design workflows, understanding your current usage patterns is an important first step.