Introduction

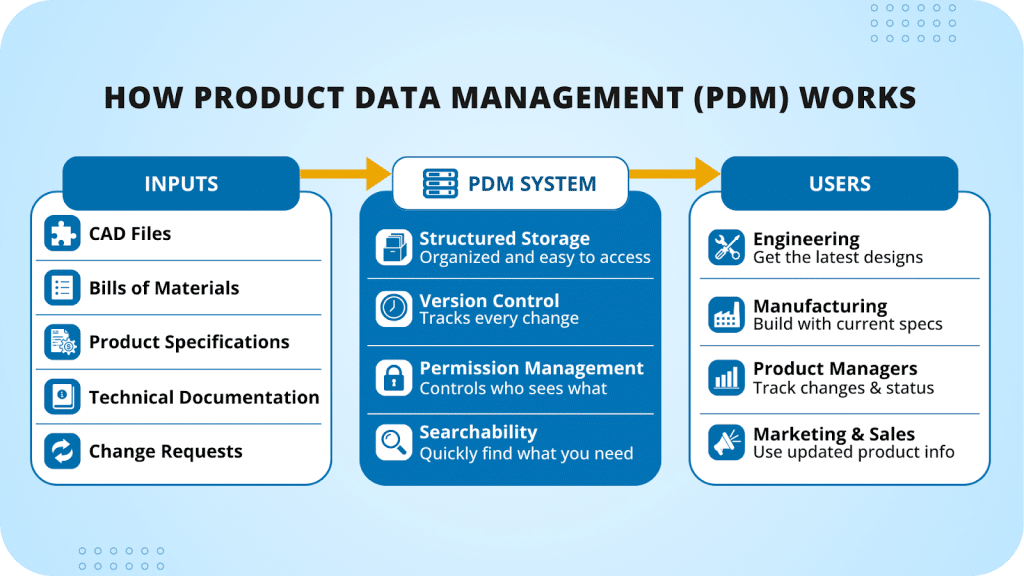

Design data is one of the most valuable assets in any manufacturing organisation. Yet many teams struggle to manage it effectively. When files are scattered, uncontrolled, or poorly structured, the cost extends far beyond inconvenience—it directly impacts quality, productivity, and risk.

When File Storage Becomes a Risk

Storing CAD files in shared folders may work initially, but problems emerge as projects scale. Engineers overwrite files, outdated drawings are sent to production, and changes are implemented without proper visibility. These are not rare incidents—they are systemic risks.

The Real Business Impact

Poor data management leads to:

- Manufacturing errors due to incorrect drawings

- Costly rework and scrap

- Missed deadlines

- Compliance and audit challenges

- Loss of critical engineering knowledge when staff leave

These issues often remain hidden until a failure occurs.

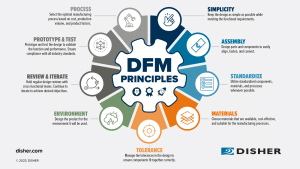

What Effective Data Management Looks Like

A structured design data management system introduces:

- Controlled file access

- Automated revision and version tracking

- Clear ownership of files

- Change traceability

- Secure collaboration across teams

This ensures everyone works from a single source of truth.

How Engineering Teams Benefit

Engineers spend less time managing files and more time designing. Managers gain visibility into project status. Manufacturing teams receive accurate, approved drawings consistently.

A Measured Transition

Adopting proper data management does not mean overhauling everything overnight. Many organisations begin with core engineering documents, establish simple workflows, and gradually expand governance.

Closing Thought

Design data management is not about control—it is about enabling trust, clarity, and accountability across the organisation.

If your team relies heavily on shared folders for design files, it may be time to evaluate more structured alternatives.