Introduction

Engineering efficiency is no longer just an internal technical matter—it has become a direct driver of business performance. For Malaysian manufacturers facing rising costs, tighter margins, and increasing customer expectations, the way engineering teams work can significantly influence profitability, delivery reliability, and long-term growth.

Engineering Decisions Shape Business Outcomes

Every design decision affects downstream processes. Delays in engineering often cascade into procurement, production, and delivery. When engineers spend excessive time searching for files, correcting drawing errors, or reworking outdated designs, the cost is not just internal—it impacts customer trust and operational stability.

Common Sources of Inefficiency in Engineering Teams

Many organisations unknowingly normalise inefficiencies such as:

- Multiple file versions stored across different locations

- Manual revision tracking using folders or filenames

- Repetitive rework caused by unclear change communication

- Limited collaboration between design and manufacturing

These challenges compound as teams grow and projects become more complex.

Engineering as a Strategic Function

Progressive manufacturing companies no longer view engineering as a cost centre. Instead, engineering is treated as a strategic capability that enables speed, quality, and scalability. Efficient workflows allow faster response to customer changes, clearer internal communication, and better decision-making across departments.

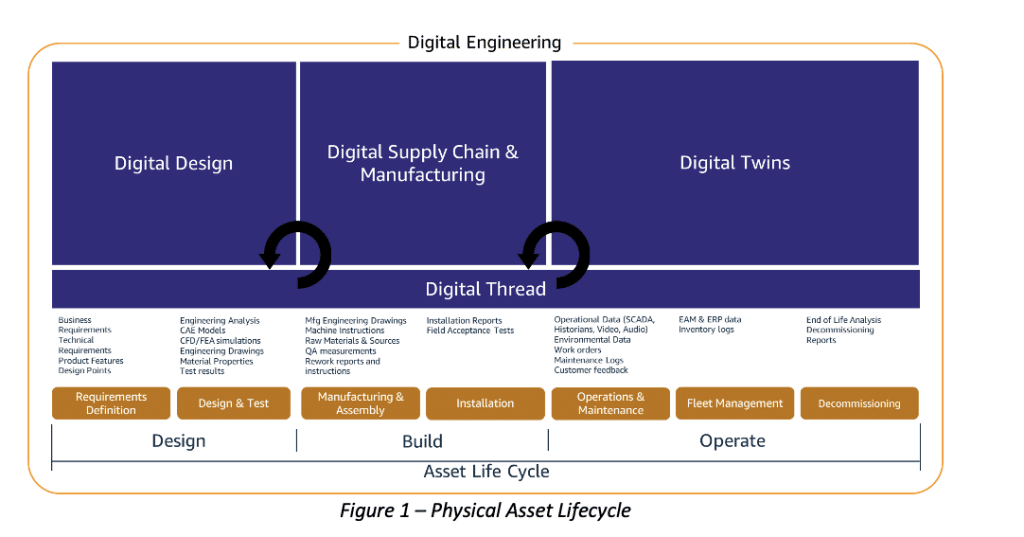

The Role of Integrated Digital Tools

Modern CAD, data management, and collaboration platforms allow engineering data to move seamlessly across teams. Solutions such as SOLIDWORKS CAD combined with structured data management provide visibility, traceability, and control—reducing risk while increasing confidence in design decisions.

A Practical Way Forward

Improving engineering efficiency does not require radical disruption. It starts with understanding current pain points, aligning tools with real workflows, and ensuring teams are properly supported with the right systems and training.

Closing Thought

For manufacturing leaders, investing in engineering efficiency is not an IT decision—it is a business decision that directly influences competitiveness and resilience.

If you are exploring ways to improve engineering performance within your organisation, a structured assessment of your current workflows is a practical first step.